The cooling system of the plastic packaging barrel mold is very important, and the effect of the cooling system determines the length of the molding cycle. The cooling time generally accounts for 80% of the entire molding cycle. For this reason, we deliberately accelerate the cooling of the deep cavity ribs and independent inserts by inserting cooling rods, and the designed cooling rod position is only 6mm away from the surface.Sonly uses refrigerant as a heat exchange medium to improve better thermal response. When the cooling rod absorbs heat at high speed, the molding cycle can be shortened by more than 30%, and fewer products with residual stress can be obtained.

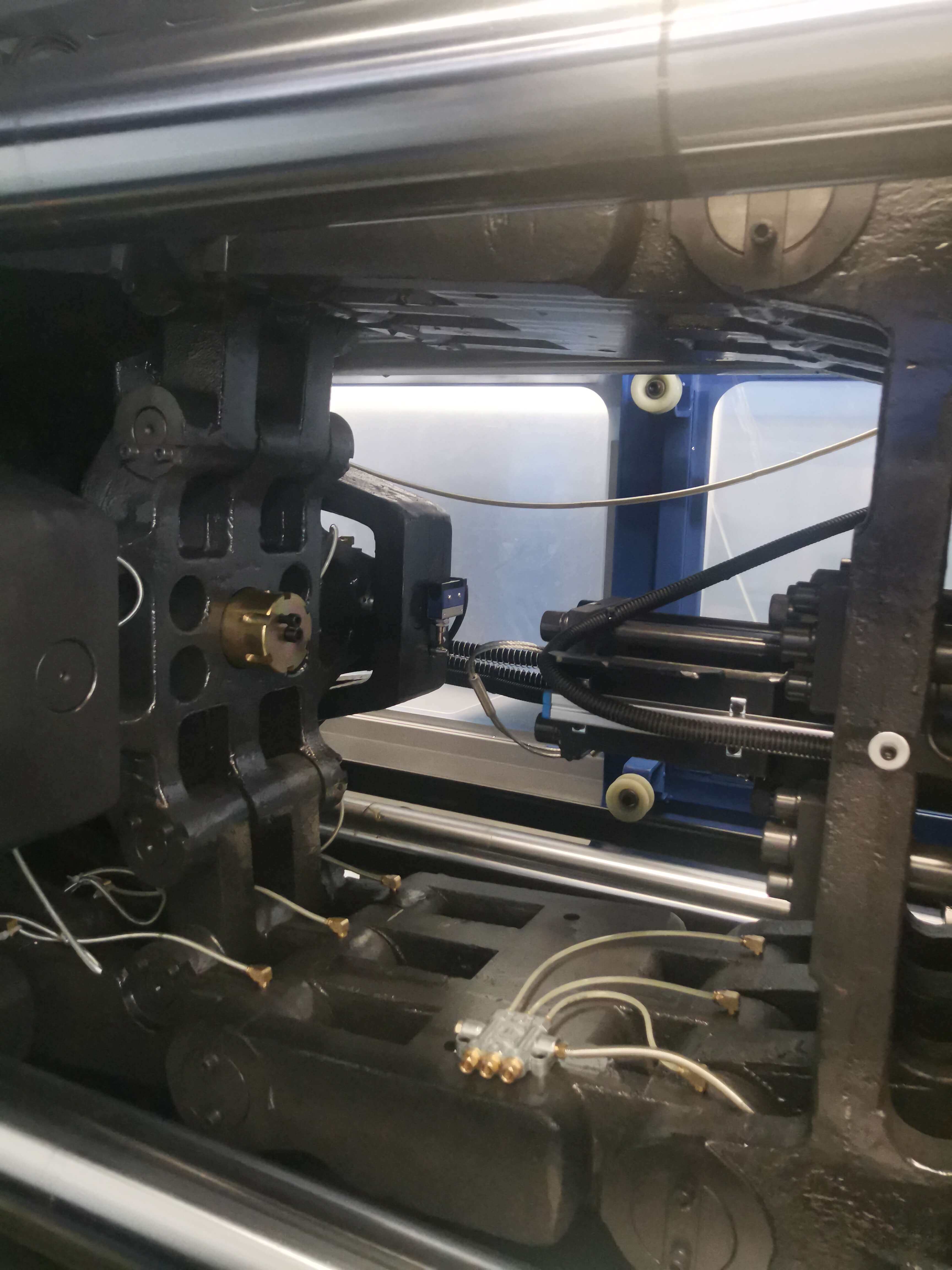

The concentricity of the plastic drum mold is an important part of the success of the project.Sonly made the packaging mold into 8-side clamping, and the clamping surface is embedded with an adjustable wear-resistant plate to ensure that the relative dimensional accuracy can reach ±0.02mm.

At the same time, during the mold clamping action of the injection molding machine, the adjustable wear-resistant plate is used, relying on the inclined surface of the clamping mold, and repeated cyclic extrusion, so as to find the center of the movable and fixed mold, and then make the precision of the adjustable wear-resistant plate reach accurate data. To ensure the concentricity of the mold clamping, and to ensure the concentricity of the plastic products, to prevent the eccentricity of the injection molding, and to achieve the purpose of short-cycle molding.

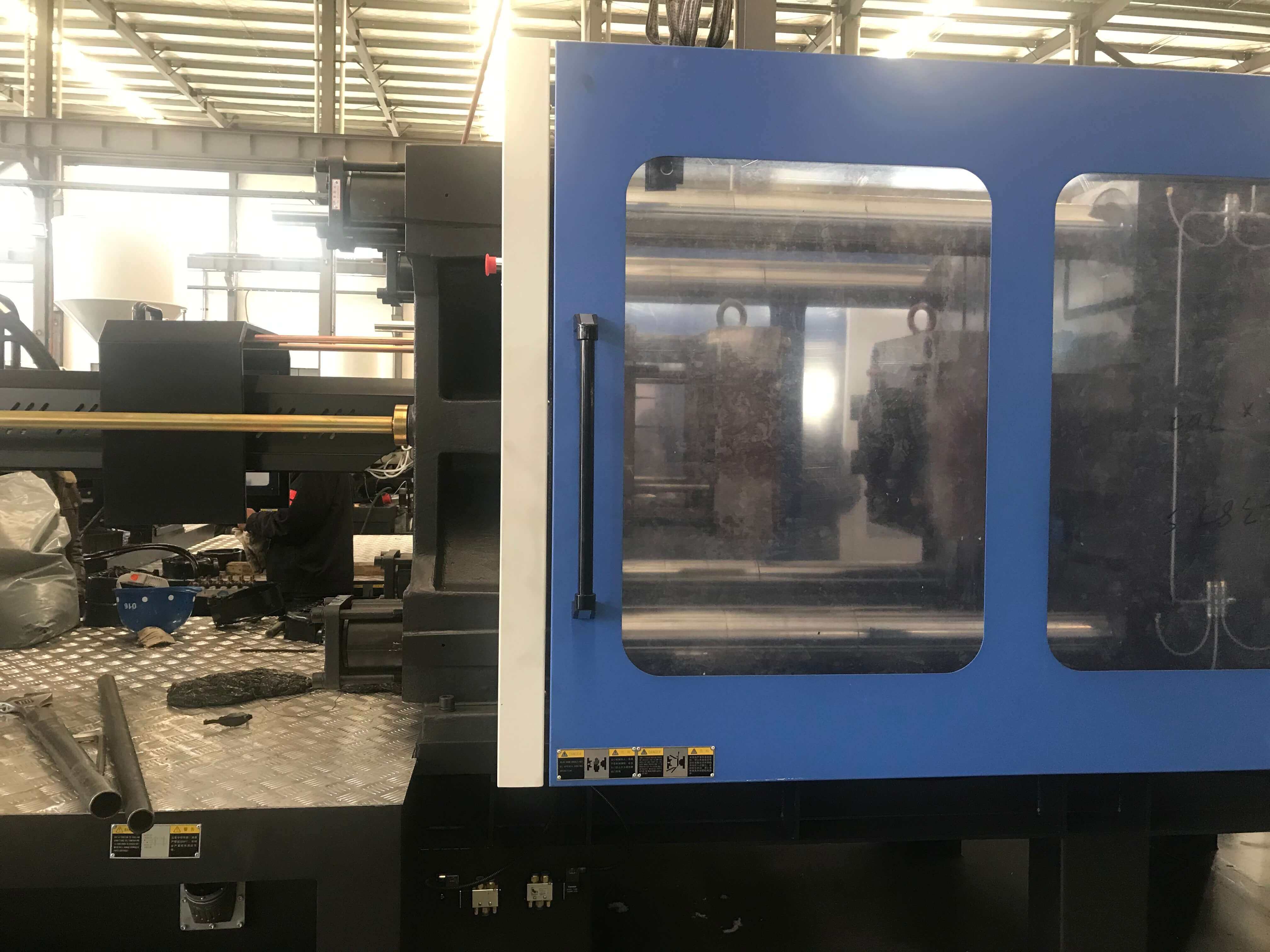

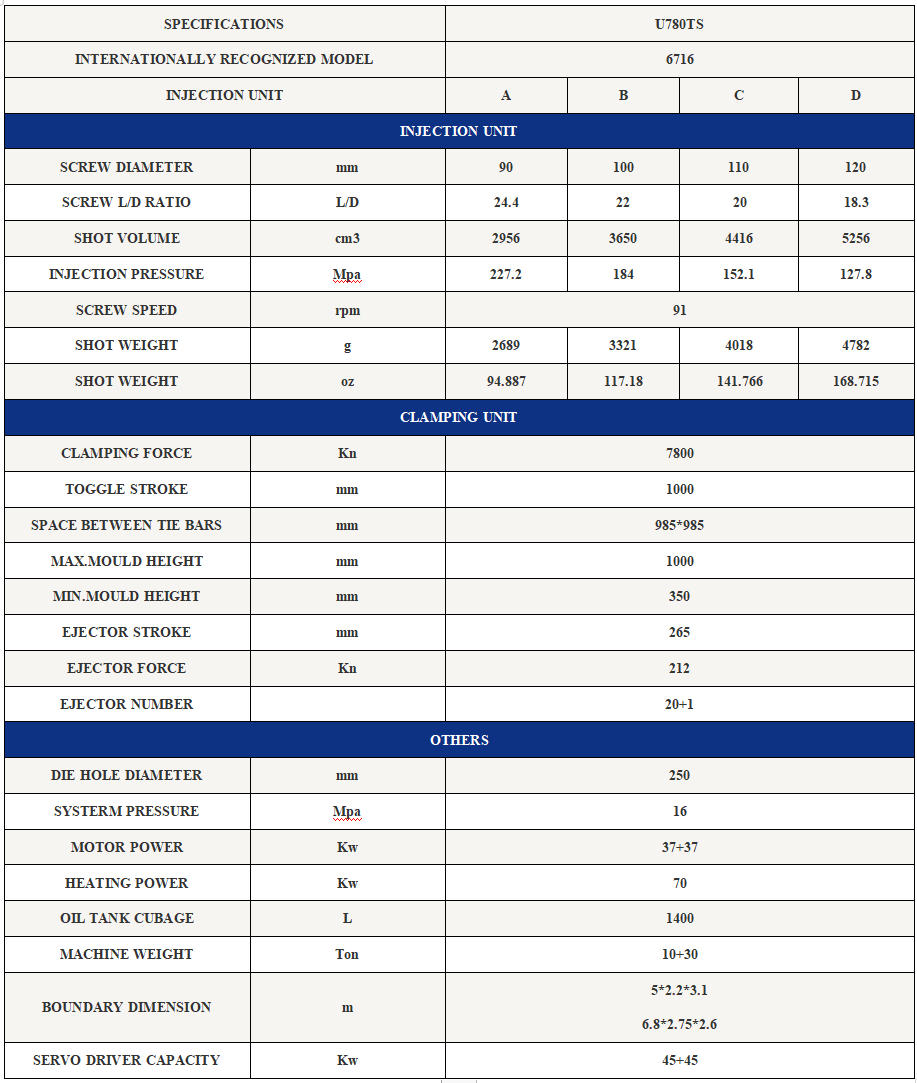

The matching of the plastic packaging barrel mold and the injection molding machine is the key factor for the success of the project. Ordinary injection molding machine can open mold after material storage and cooling, while Sonly injection molding machine adopts European advanced computer controller and horizontal bar injection system, and is equipped with high-response servo system to realize material storage, mold release and mold opening at the same time. The three-axis linkage technology carried out greatly shortens the product injection molding cycle.